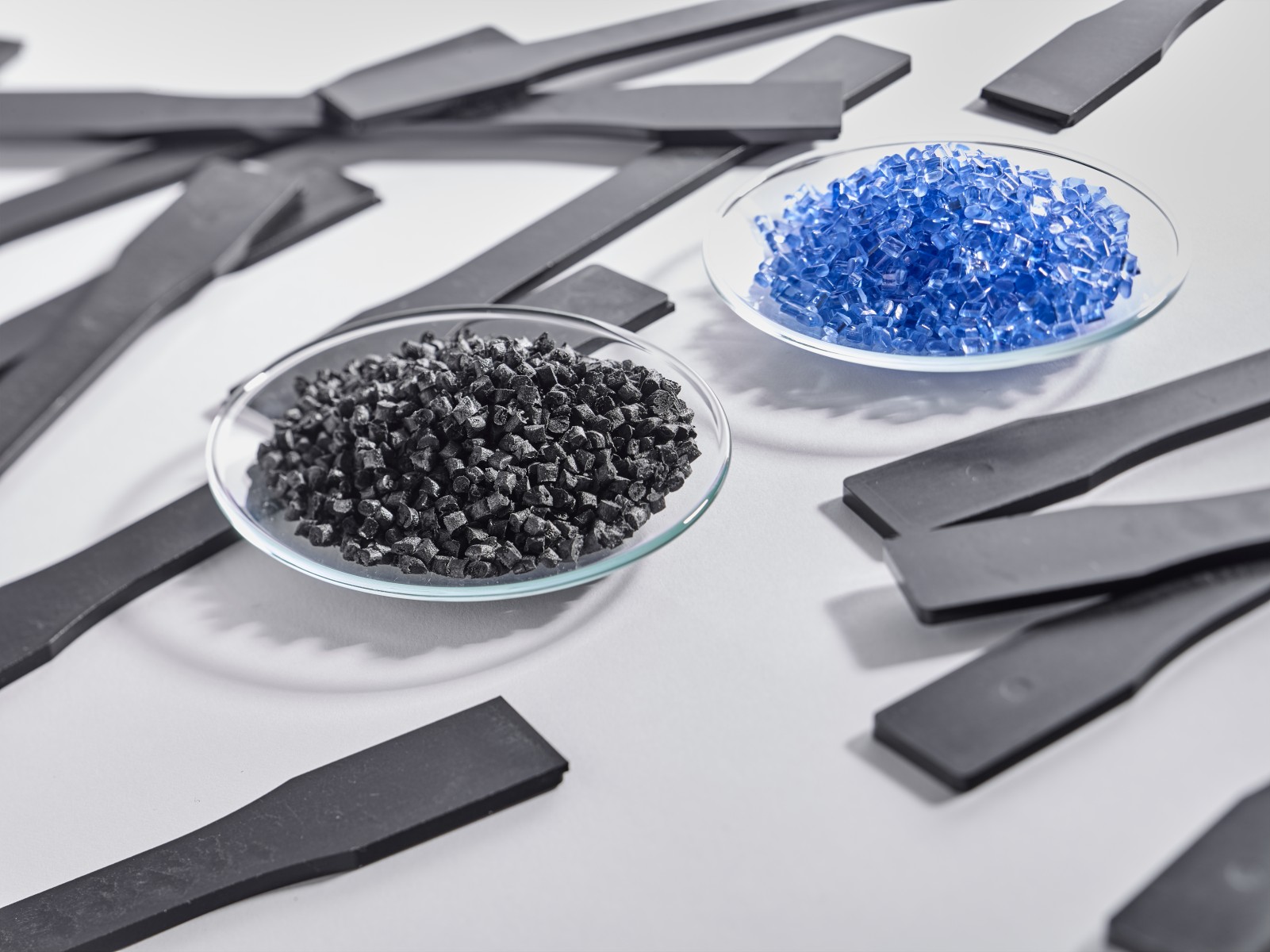

Recycling of polycarbonate composites

Cooperation with recycling specialist carboNXT?

- Production waste is a valuable raw material

- Reprocessing on an industrial scale possible

- Contribution to more sustainability and resource conservation

The Maezio® brand of continuous fiber-reinforced polycarbonate composites (CFRTPs) developed by ÃÜÌÒAV are characterized by their extremely light weight, very high strength and exceptional flexibility of design. This means that waste generated during the production of composites also becomes a valuable raw material. However, because they consist of different materials that cannot be easily separated from one another, the recycling of composites is a challenge. ÃÜÌÒAV is cooperating with recycling specialist carboNXT® on this. It has developed a process that allows the waste to be processed on an industrial scale.

"We are very excited about this joint solution, as we cannot process the materials ourselves for technical reasons," explains Lisa Ketelsen, Head of Thermoplastic Composites at ÃÜÌÒAV. "By recycling according to type at our partner's plant, the raw materials can be converted back into valuable products with similarly good properties as those characteristic of virgin materials. The recycling of materials makes it possible to use them again in other products. In this way, we save raw material resources and contribute to the focus on the circular economy."

"Our company has many years of experience in recycling carbon fiber-reinforced thermoplastics and has the necessary plant technologies to process such waste. We were therefore the partner of choice for this task," says Tim Rademacker, general manager at Mitsubishi Chemical Advanced Materials and responsible for the carbon fiber recycling business. "From the processed waste, we produce high-quality new compounds of carbon fiber-reinforced polycarbonate for ÃÜÌÒAV at CarboNXT®."

Demand for such recycled products is high because they are valuable raw materials, but also because more and more industrial customers and consumers are looking for more sustainable products. The project will now be further developed to market maturity by ÃÜÌÒAV, Mitsubishi Chemical Advanced Materials and possibly other partners. It is part of a global strategic program with which ÃÜÌÒAV is focusing all its energy on the circular economy.

About ÃÜÌÒAV:

ÃÜÌÒAV is one of the world¡¯s leading manufacturers of high-quality polymer materials and their components. With its innovative products, processes and methods, the company helps enhance sustainability and the quality of life in many areas. ÃÜÌÒAV supplies customers around the world in key industries such as mobility, building and living, as well as the electrical and electronics sector. In addition, polymers from ÃÜÌÒAV are also used in sectors such as sports and leisure, telecommunications and health, as well as in the chemical industry itself.

The company is geared completely to the circular economy. In addition, ÃÜÌÒAV aims to achieve climate neutrality for its Scope 1 and Scope 2 emissions by 2035, and the Group¡¯s Scope 3 emissions are also set to be climate neutral by 2050. ÃÜÌÒAV generated sales of EUR 14.2 billion in fiscal year 2024. At the end of 2024, the company had 46 production sites worldwide and employed approximately 17,500 people (calculated as full-time equivalents).

Forward-Looking Statements

This news release may contain forward-looking statements based on current assumptions and forecasts made by ÃÜÌÒAV. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. These factors include those discussed in ÃÜÌÒAV¡¯s public reports which are available at www.covestro.com. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.